The construction industry is responsible for a substantial share of global carbon emissions, driving climate change and resource depletion. According to the World Economic Forum, buildings and infrastructure account for roughly 40% of global carbon emissions. A significant and growing portion of these emissions — known as embodied carbon — comes from materials and construction. Given Deloitte’s forecast that total construction activity will reach US$16.11 trillion by 2030, driven primarily by ongoing urbanization in Asia, the embodied-carbon burden is likely to intensify. Yet commitments to net-zero building stock, stricter regulations, and decarbonization targets are pushing the global building sector to rethink construction practices and accelerate the adoption of low-carbon approaches.

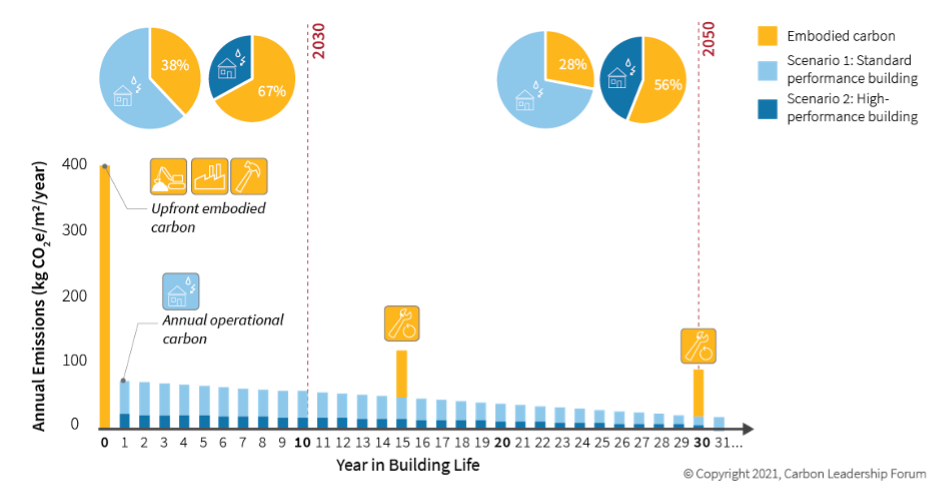

Since as much as half of a building’s lifetime emissions can be “locked in” before it’s even occupied, the way construction sites operate — from material use to waste handling — is critical. While climate policy, building regulations, and design decisions set the framework, construction sites’ day-to-day actions determine whether sustainability goals are actually achieved. The good news is that there are many practical strategies to reduce emissions, cut resource use, and improve compliance at the site level. This article outlines eight of them, each contributing to more sustainable construction sites.

Table of Contents

1. Choose Sustainable Building Materials

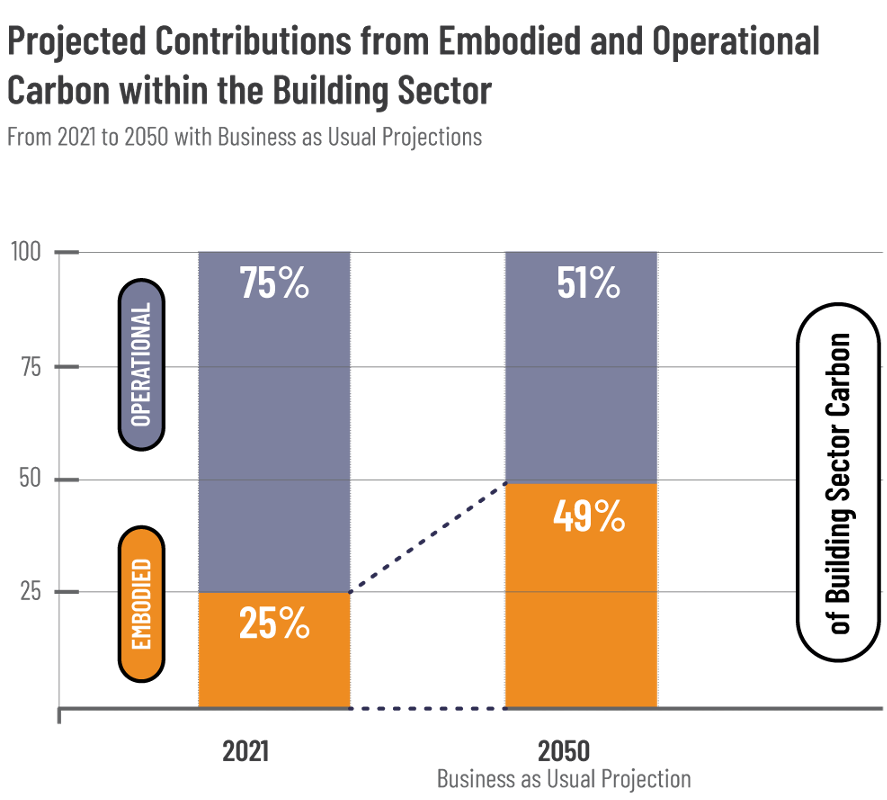

Construction materials have a significant impact on a building’s lifetime emissions. Concrete, steel, and aluminum alone are responsible for 23% of total global emissions. Within the construction sector, the share of embodied carbon from materials is projected to reach 49% by 2050. This makes material selection a powerful lever for creating sustainable construction sites. Opting for materials from renewable sources, with low embodied carbon and high recycled or bio-based content, can significantly reduce a building’s carbon footprint. These materials have a lower environmental impact across their lifecycle — from sourcing to disposal — and may include natural composites. Many can also be reused at the end of a building’s life, helping cut carbon emissions, conserve resources, and reduce landfill waste.

1.1 Examples of Sustainable Building Materials

- Bio-Based and Renewable Materials – Bamboo, hemp, straw, and certified sustainable timber (e.g., CLT, Glulam) that offer low carbon footprints and natural durability.

- Innovative Low-Carbon Composites – Hempcrete, Timbercrete, Ferrock, and bio/mineral-based self-healing materials that combine recycled and natural components, delivering strength, insulation, and carbon sequestration benefits.

- Low-carbon and Recycled Concrete Solutions – Mixes using recycled aggregates, supplementary cementitious materials (calcined clay, natural pozzolans, ground glass), and locally sourced byproducts to reduce cement use.

- Recycled and Circular Materials – High-quality recycled steel, glass, plastics, and rubber from verified sources, reducing demand for virgin resources.

- Low-Emission Finishes – Ultra-low or zero-VOC paints, sealants, and coatings that improve indoor air quality and reduce harmful emissions during application and use.

- Materials Manufactured Using Advanced Methods – Modular construction, automated fabrication, and 3D printing that exclusively use low-carbon, recycled, or bio-based feedstocks, reducing waste, improving precision, and cutting transportation-related emissions.

The right material choices can help ensure a sustainable construction site while delivering long-term performance, regulatory compliance, and measurable environmental gains.

2. Reduce Energy Consumption

Across their lifecycle, buildings are responsible for 30–40% of primary energy consumption. Within that footprint, construction sites consume a substantial amount of energy for lighting, machinery, and temporary facilities to support site operations and the construction process. During the construction phase, about 7–10% of a building’s total embodied energy is consumed. Lowering on-site energy demand can deliver both immediate cost savings and substantial carbon reductions while contributing to more sustainable sites.

2.1 Practical Strategies to Reduce On-Site Energy Use

- Energy-Efficient Equipment – Use LED site lighting, hybrid or electric machinery, and equipment with high energy-performance ratings.

- On-Site Renewable Generation – Install solar photovoltaic (PV) panels, small wind turbines, or hybrid generators to power site cabins, lighting, and tools.

- Smart Energy Management – Deploy sensors, timers, and load-management systems to avoid unnecessary runtime and idle energy use.

- Efficient Temporary Facilities – Choose insulated, well-sealed site offices and storage units to reduce heating and cooling loads.

- Early-Stage Design Coordination – Plan for passive heating, cooling, and natural light to minimize long-term operational energy needs.

Treat energy as a managed KPI from day one to reduce construction sites’ overall demand. Set on-site energy targets in tenders and contracts, track performance weekly, and align equipment and temporary works. By doing so consistently, you can cut fuel and electricity use, reduce upfront embodied impacts, and lower operating costs without slowing delivery.

3. Minimize Waste

The World Bank projects global municipal solid waste to reach ~3.40 billion tons by 2050. Separate studies estimate that construction and demolition waste (CDW) —including debris, packaging, and surplus materials from building projects — accounts for at least 30% of global solid waste, making construction a major source of environmental impact. Given that up to one-third of construction materials can become waste — and disposal costs typically run $66.70–$78.00 per cubic yard — developing strategies to reduce CDW is essential for lowering operational costs and improving construction site sustainability.

3.1 Ways to Minimize Waste on Construction Sites

- Use Prefabricated Components – Manufacture off-site and standardize assemblies to reduce offcuts, rework, and on-site waste.

- Design for Material Efficiency – Use building information modeling (BIM), standardized grids, and take-back specs to optimize quantities and avoid surplus.

- Recycle and Segregate Waste – Divert concrete, metals, wood, and other recoverable materials from landfills.

- Reduce and Reuse Packaging – Opt for reusable or returnable containers and limit excess packaging.

- Compost Organic Waste – Process food scraps and plant material into usable fertilizer where permitted.

- Prioritize Deconstruction Over Demolition – Salvage usable materials for resale or reuse.

- Train Site Personnel – Ensure crews follow waste minimization and recycling protocols consistently.

Cutting construction site waste reduces disposal costs, conserves materials, and lowers the project’s environmental footprint — turning efficiency into both a financial and sustainability win.

Read also: Understanding the 5 Types of Construction Project Costs

4. Manage Water Use

Roughly 4 billion people face severe water scarcity for at least one month each year, and global water withdrawals are projected to rise by ~55% by 2050. According to the World Green Building Council, buildings and construction account for about 15% of global freshwater use. While a significant amount of water is used during the operational phase of buildings, construction sites draw heavily for wet trades, tool washing, groundwork, dust suppression, moist curing, and landscaping — creating real exposure to water-use limits and permit conditions, fines, and schedule risks in water-stressed regions. With pressure mounting to reduce consumption, the most effective strategy is to build water-saving measures into construction site planning and daily operations.

4.1 Ways to Manage Water Use on Construction Sites

- Collect and Reuse Non-Potable Water – Harvest rainwater and recycle treated graywater for site cleaning, dust suppression, equipment washing, and mixing.

- Install Low-Flow Fixtures and Fittings – Fit low-flow faucets, toilets, and hose nozzles in site cabins and temporary plumbing.

- Install Leak-Detection Systems – Monitor hoses, tanks, and temporary plumbing to prevent unnoticed water loss.

- Schedule Water-Intensive Activities – Perform them during cooler periods to reduce evaporation losses.

- Adopt Water-Efficient Landscaping – Use xeriscaping and native plants to minimize irrigation and maintenance on landscaped sites.

Reducing dependence on potable water lowers operating costs, eases compliance in water-stressed areas, reduces energy and emissions linked to water supply and treatment, and strengthens a construction site’s sustainability credentials.

5. Prioritize Sustainable Transportation

Transportation accounts for around 15% of global greenhouse gas (GHG) emissions. In construction projects, material transport to the site typically contributes ~2–6% of upfront embodied carbon, while transport and on-site activities during construction can reach ~10–16% for heavy infrastructure — smaller than materials or energy use, but still a meaningful lever to improve construction site sustainability. Transport to and from sites can also be a significant source of fuel costs and compliance risk, especially in cities with low-emission zones and congestion charges. Optimizing transport strategies can cut operating expenses, improve logistics, and reduce regulatory exposure.

5.1 Sustainable Transportation Options for Construction Sites

- Electrify Site Vehicles and Machinery – Use electric vans, telehandlers, forklifts, and excavators where feasible.

- Coordinate Logistics – Group material deliveries, schedule drop-offs, and enforce no-idling policies to cut trips, delays, and congestion.

- Support Worker Transit – Provide shuttles, shared transport, or transit passes to reduce single-occupancy commutes.

- Enable Active Travel – Offer secure bike storage, changing facilities, or small incentives to encourage walking and cycling.

Opting for sustainable construction site transportation is not just about environmental stewardship — it’s cost control, compliance protection, and a competitive edge in tenders where sustainability criteria are scored. By prioritizing these options, construction sites can cut transport-related GHG emissions and make their operations more sustainable.

6. Implement Green Design Strategies

Green design strategies prioritize sustainability from the earliest project stages, helping cut a building’s lifetime emissions, meet ESG criteria, and align with net-zero goals. Global building floor area is expected to increase by ~75% between 2020 and 2050, and as grids decarbonize, upfront emissions in new construction can account for around half of whole-life carbon. Because up to half of a building’s lifetime emissions can be locked in during early design decisions, integrating low-carbon design strategies is both an environmental and compliance imperative.

6.1 Examples of Green Design Strategies

- Orientation, Daylighting and Passive Solar – Position the building for sun and daylight, right-size glazing, and add daylight sensors to cut heating, cooling, and lighting loads.

- Green Roofs and External Shading – Specify green-roof coverage and soil depth, use high-reflectance roof finishes, and add overhangs and louvers to sun-exposed facades to reduce heat gains, cooling demand, and stormwater runoff.

- Natural Ventilation and Passive Airflow – Use vents, atria, and cross-ventilation to reduce reliance on mechanical cooling.

- Material Efficiency – Use reusable modular formwork, standardized, prefabricated components, and regular structural grids to minimize offcuts, reduce concrete and steel quantities, and lower embodied carbon.

- Embodied-Carbon Tools – Set benchmarks, track impact, and inform procurement using standardized lifecycle assessment (LCA) methods and databases.

By implementing green design strategies, teams can reduce a building’s lifetime environmental impact, meet ESG criteria, support certifications such as LEED and BREEAM, and improve access to green finance during design and construction. Doing so positions the project for green refinancing at completion and helps ensure compliance with emerging whole-life carbon requirements — creating a clear competitive advantage.

7. Reduce Noise Pollution

Excessive noise from construction sites affects nearby residents and wildlife, disrupting habitats and behavior. For workers, hazardous exposure begins around 85 dBA over an 8-hour shift, while community guidelines target ~70 dB LAeq,24h to prevent hearing impairment. Many common site tools — such as concrete mixers, jackhammers, and pile drivers — typically produce 85–100 dBA at 50 ft (≈15 m), so unmanaged noise can cause hearing loss, complaints, and enforcement action. Many cities enforce strict noise regulations; non-compliance can result in fines, delays, or reputational damage. Effective mitigation requires proactive planning and technology, making noise reduction a core element of sustainable construction.

7.1 Examples of Construction Site Noise-Reduction Measures

- Install noise barriers and acoustic screens at the site perimeter to block and absorb sound.

- Specify low-noise equipment and machinery with improved mufflers and damping systems.

- Schedule the loudest activities during permitted hours to minimize disturbance.

- Maintain equipment regularly to prevent excess noise from wear or malfunction.

- Implement real-time noise monitoring to track hotspots, trigger alerts, and document compliance.

Integrating noise-control strategies into project planning reduces environmental and social impact, supports compliance with permit conditions and tender requirements, and strengthens bid credibility where noise performance is scored.

8. Educate Workers and Contractors

Educating workers and contractors is essential to delivering sustainable construction in practice. On-site performance depends as much on human behavior as on strategy or design: crews directly influence material use, waste generation, energy and water consumption, and adherence to environmental rules. Targeted on-site training improves environmental performance and helps site teams meet client and regulatory requirements and earn credits in certifications such as LEED and BREEAM—factors that can influence funding, permitting, and tender scoring.

8.1 Topics to Cover in Sustainable Construction Site Training

- Sustainable material handling – How to select, store, and use low-impact materials to minimize damage and offcuts.

- Energy conservation – How to use temporary lighting, equipment, and site power efficiently, and adopt no-idling practices.

- Waste reduction and segregation – How to implement clear processes for reuse, recycling, and compliant disposal.

- Water management – How to minimize water use in processes and prevent runoff contamination.

- Low-carbon transport – How to enable shared transport, efficient driving, and reduce idling.

- Link to design intent – How site choices affect long-term building performance and embodied-carbon impacts.

- Delivery and governance – How to run it — site inductions, toolbox talks, role-based step-by-step instructions and checklists, multilingual materials, and periodic audits.

Well-structured training builds a culture of accountability, reduces operational inefficiencies, improves compliance evidence for audits and tenders, and surfaces on-site ideas for continuous improvement. A trained workforce not only executes sustainable construction practices but also actively identifies opportunities for improvement, making sustainability a continuous process rather than a one-off initiative.

Conclusion

Creating more sustainable construction sites is critical to reducing construction’s environmental impact and building a more sustainable future. The construction industry must continue to innovate, adopt low-carbon materials and design approaches, and enforce disciplined execution every day.

Implementing site-level strategies to reduce energy consumption, minimize waste, manage water use, prioritize sustainable transportation, reduce noise pollution, and educate workers and contractors can make a significant contribution to any site. Done well, this cuts costs and risks, meets compliance requirements, and delivers a better-performing building from day one.

Related posts

Read our other articles where you can find useful and relevant information about improving your construction site efficiency:

- 10 Tips on How to Improve Construction Site Efficiency

- Enhancing Construction Efficiency: Key Factors and Strategies

About the Author

Taavi Kaiv

Taavi Kaiv is a construction specialist with over ten years of experience in the construction industry. Taavi is an accomplished construction project manager with many successful projects that have been completed under his guidance. Taavi holds a master’s degree in construction management from the Tallinn University of Technology. View profile