If you work in construction, you’re familiar with purchase orders. These documents are crucial for keeping a project on budget, so it’s important to know how they function and how to use them correctly.

Table of Contents

What is a purchase order in construction?

In construction, a purchase order is a document that details the prices and quantities of materials or services required to complete a project. It represents an agreement between the buyer (typically the project owner or a general contractor) and the seller (typically a contractor or a subcontractor). The buyer issues this purchase order to the seller to cover the costs associated with the project.

What information does a construction purchase order contain?

A construction purchase order typically includes several important pieces of information to ensure that both the buyer and the supplier clearly understand the terms of the transaction. Here are the key details that are usually found in a construction purchase order:

- Purchase Order Number: A unique identifier that helps track and manage the order.

- Buyer’s Information: This includes the name, address, and contact details of the company or individual purchasing the goods or services.

- Seller’s Information: The name, address, and contact details of the supplier or contractor providing the materials or services.

- Description of Goods or Services: A detailed description of each item or service being purchased, possibly including specifications, sizes, weights, or other relevant details.

- Quantity: This part of the document specifies the number of items required. It informs the seller of the order size so they can ensure the correct amount.

- Unit Price: This shows the price for each unit of the item. By multiplying the unit price by the number of units, you can figure out the total cost. This calculation helps the buyer and seller see the monetary value of the order.

- Total Cost: The overall cost of the order, including a breakdown of taxes, discounts, or additional charges if applicable.

- Delivery Date(s): This part of the document outlines when the items or services are expected to be delivered or completed. It helps the buyer schedule their project accurately and ensures everything is delivered on time.

- Delivery Location: The specific location where the goods should be delivered or services provided.

- Payment Terms: Details on how and when the payment will be made, including preferred payment methods and any installment plans, if applicable.

- Authorization: Signatures or other forms of authorization from the buyer indicating approval of the purchase order.

These elements help define the purchase’s scope, manage expectations, and provide a legal foundation for the transaction.

Types of purchase orders in construction

In construction, different purchase orders are used based on the project’s needs. Here are three common types:

1. Standard Purchase Orders

This type is widely used to buy construction materials or services that are not part of an ongoing supply deal. A standard purchase order lists how much something is needed, its cost, and when it should be delivered. For instance, if a construction firm needs certain materials for a project, they would place a standard purchase order with the details of the quantity, price, and delivery date clearly stated. This ensures that everyone knows precisely what is expected and helps keep the purchasing process organized.

2. Planned Purchase Orders

These are used for purchases that are expected to happen regularly over time. This type of order lets companies prepare and budget well in advance. For example, if a project will need lots of materials over several months, a construction company might use a planned purchase order to tell the supplier how much they’ll need each month. This helps both the construction company and the supplier plan better and keeps materials flowing smoothly throughout the whole project timeline.

3. Blanket Purchase Orders

These are for ongoing needs with a particular supplier, usually set for a year. Blanket orders make getting items or services needed regularly easier and quicker. For instance, if a construction company frequently rents equipment from the same supplier, it might set up a blanket purchase order. This way, it can get equipment throughout the year under pre-agreed terms without making a new order each time.

How do contractors write purchase orders?

Contractors have various ways to write purchase orders, each with its own methods to increase efficiency and incorporate technology to make the purchase order process smoother.

Manual Methods:

Some smaller or more traditional residential construction companies still use manual methods to create purchase orders. They might write the details on a printed document, which subcontractors then sign. This approach covers the basics of initiating a purchase order. However, relying solely on paper has its downsides, such as the risk of losing these documents or not having access to them when needed. To mitigate these risks, many companies are moving towards digital solutions.

Purchase Order Software:

Automated construction purchase order software is essential for many construction companies, especially those dealing with multiple suppliers. This software typically includes features that manage purchase orders and other financial aspects like estimates, invoices, and billing. However, while these tools are useful, they often do not integrate all aspects of a project, which can limit their effectiveness. It’s beneficial to choose software that connects purchase orders with other project components like subcontractor billing, client selections, and overall project management.

In the construction industry, managing purchase orders can be challenging. Storing them in physical files seems straightforward, but it’s not very practical. With potentially hundreds of purchase orders per project, locating a specific one among stacks of paper can be overwhelming. Furthermore, these documents are often not accessible when needed at a construction job site.

Fortunately, technological advancements have made it easier to handle purchase orders digitally. Various software solutions, like Bauwise, are now available that not only store these documents online but also allow contractors to create and monitor them. Bauwise purchase order software helps track the approval status of orders, ensures the delivery of items, and confirms when payments have been made.

What does a construction purchase order look like?

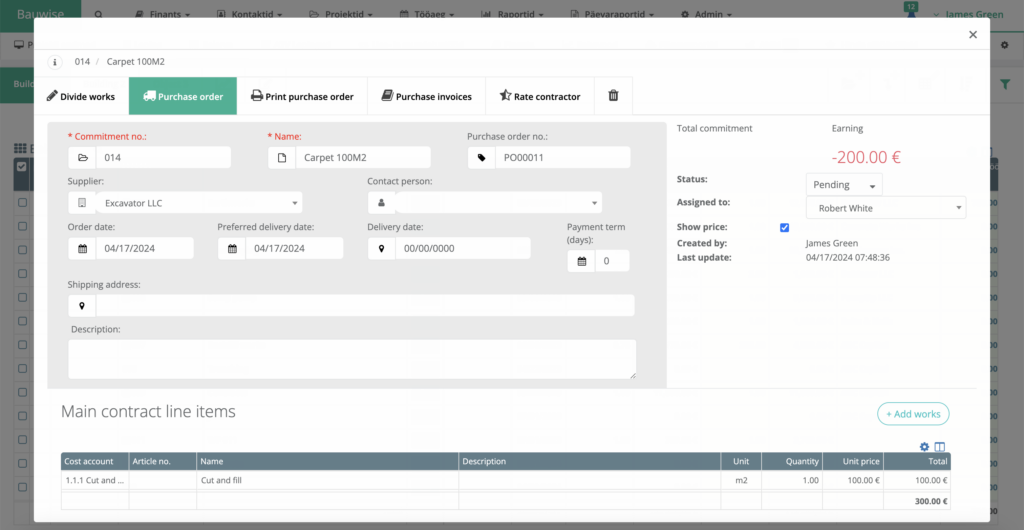

Here is an example of a construction purchase order in Bauwise purchase order management software:

Construction purchase order template

Here, you can download the construction purchase order template and use it when managing construction projects:

Construction Purchase Order Template

FAQ

In this section of this blog post, we answer the most frequently asked questions about construction purchase orders.

When is a construction purchase order needed?

A construction purchase order is made when a product or service is needed for a project. If you need to buy something, you send a purchase order to a supplier, who can accept, reject, or suggest a different agreement.

The purchase order can be sent directly to the supplier for smaller orders. It is usually sent by the customer who needs the project done.

For more significant projects, the process is a bit different. Project managers, contractors, trade partners, or subcontractors must first send a purchase requisition to their purchasing team. This is basically asking for permission to create a purchase order. The purchasing department checks the requisition, and if everything is okay, they create and send the purchase order to the supplier.

What is the difference between a construction purchase order and an invoice?

A construction purchase order and an invoice are crucial documents in the procurement process, but they serve distinct roles at different stages. At the start of a transaction, the buyer issues the purchase order to the seller. It details what goods or services are needed, specifying the type, quantity, and price, and authorizes the seller to supply them. Once accepted by the seller, it becomes a legally binding contract outlining what should be delivered and what will be paid.

On the other hand, an invoice is sent by the seller to the buyer after the goods have been delivered or services rendered. It is a billing document that lists what has been provided, including quantities and prices, and formally requests payment based on the delivery. Essentially, while the purchase order sets the terms and initiates the order, the invoice confirms delivery and requests payment, reflecting the actual goods delivered or services provided.

What is the difference between a construction purchase order and a contract?

A construction purchase order and a project contract are both essential in a construction project, but they serve different purposes and have various levels of complexity and legal standing.

A construction purchase order is typically a document sent from a buyer, such as a construction company, to a supplier or contractor specifying the goods or services required. It details item type, quantity, and price and becomes legally binding document when the supplier accepts it. Purchase orders are straightforward, focusing mainly on procuring specific goods or services.

In contrast, a contract in construction is a comprehensive legal agreement that outlines the scope of the entire project or significant parts of it. It is an extensive document that includes not just what is to be delivered but also detailed terms about timelines, payment schedules, quality standards, each party’s responsibilities, and how to handle disputes or terminations. Contracts are designed to manage the complete relationship and obligations between all parties involved, such as owners, main contractors, subcontractors, and suppliers.

Thus, while a purchase order is a specific instruction for buying products or services, a project contract provides the framework for the entire construction project, detailing every aspect of the relationship and responsibilities between two parties.

What is the difference between a purchase order and a subcontract?

A purchase order is a document issued by a buyer (like a project manager or general contractor) to a supplier or vendor authorizing the purchase of goods or services. It specifies the type, quantity, and price of the items ordered. Purchase orders are used primarily for transactions involving materials or small-scale services. They become legally binding once the supplier accepts them but typically cover only the specific details of what is being bought, how much it costs, and when it will be delivered.

A subcontract, on the other hand, is a contract agreement used to delegate part of the main construction contract from a general contractor to a third party, known as a subcontractor. This usually involves specialized work such as electrical, plumbing, HVAC, or roofing. Subcontracts are more complex than purchase orders and include detailed terms about the scope of work, timelines, payment schedules, quality standards, and other contractual obligations. They are legally binding contracts that establish a direct contractual relationship between the general contractor and the subcontractor to perform a particular scope of work in the project.

What is a subcontractor purchase order?

A subcontractor purchase order is a specific type used within the construction industry. It is issued by a general contractor or a higher-tier subcontractor to a lower-tier subcontractor or supplier. This document authorizes and specifies the purchase of materials, supplies, or services needed for a construction project.

The purpose of a subcontractor purchase order is to formally request and outline the details of goods or services that a subcontractor needs to complete their portion of a project. It functions similarly to any other purchase order but is directed explicitly from one subcontractor to another or from a subcontractor to a supplier.

This document typically includes information such as:

- The types and quantities of materials or services required.

- The agreed-upon prices for these items.

- Delivery dates and locations.

- Payment terms.

About the Author

Mikk Ilumaa

Mikk Ilumaa is the CEO of Bauwise, a leader in construction financial management software with over ten years of experience in the construction software industry. At the helm of Bauwise, Mikk leverages his extensive background in developing construction management solutions to drive innovation and efficiency. His commitment to enhancing the construction process through technology makes him a pivotal figure in the industry, guiding Bauwise toward setting new standards in construction financial management. View profile